OST-2000 UPVC Processing Center

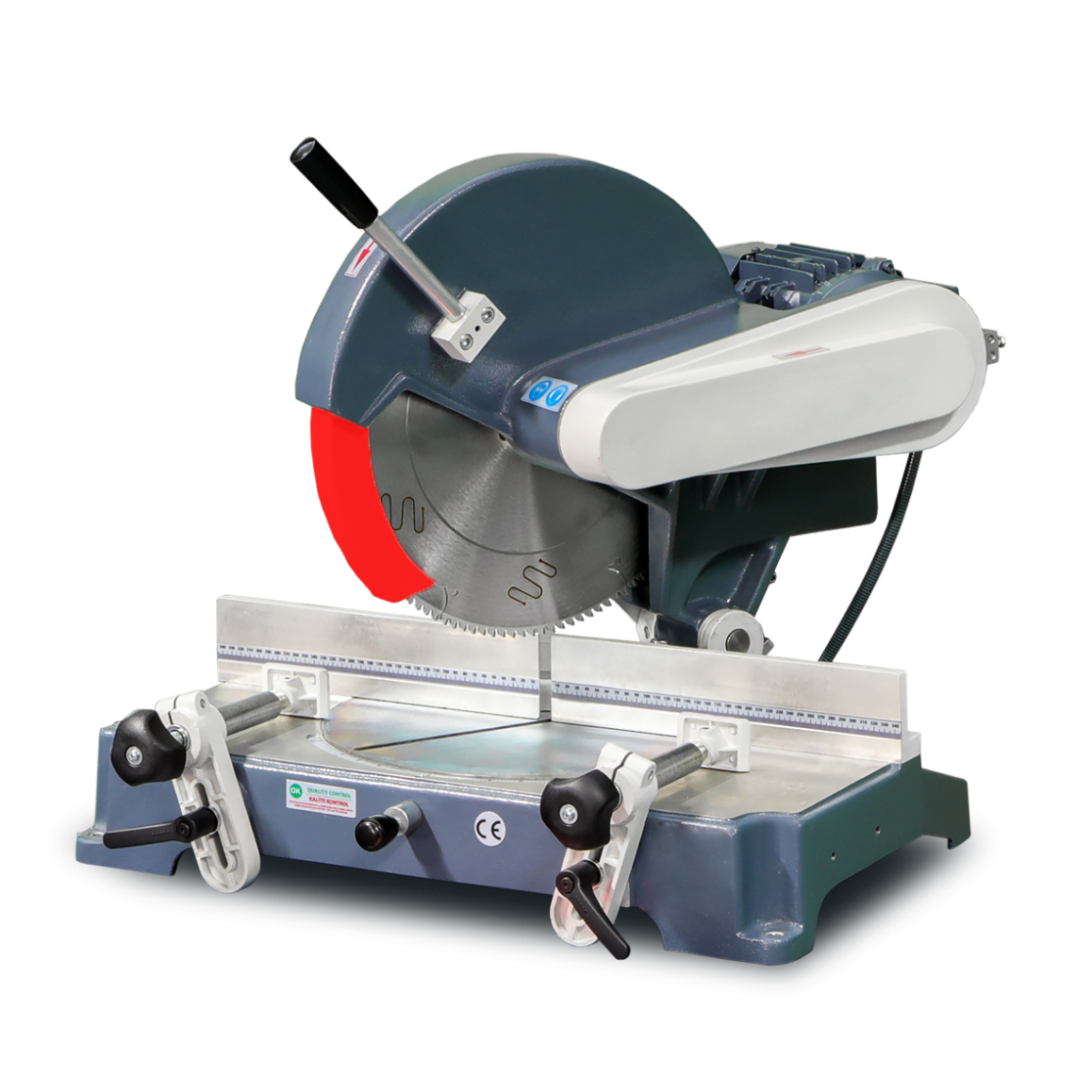

PVC Machine

- Ability to perform operations such as channel opening, drilling, marking, cutting at different angles, etc.

- 10 high-speed, air-cooled spindle motors specially designed for aluminum

- Average axis speeds exceeding 140 m/min

- Precision 3-axis profile holding gripper

- Profile feeding capacity: 7 profiles

- Maximum profile processing length: 6500 mm, minimum: 400 mm

- Automatic profile length detection feature

- Windows-based, easily adjustable, user-friendly interface

- Data transfer via USB, online remote monitoring system

- Remote connection support

- 23.8” high-performance touchscreen

- Servo-controlled cutting unit that provides cutting angles from 30° to 150°, with a precision of ± 0.1°

- Automatic conveyor system for transporting cut waste profiles to the collection bin

Standard Equipment:

- Ø550 mm saw

- Automatic scrap and chip conveyor discharge unit

- Barcode printer

Optional Equipment:

- Compatibility with CAM software

- Customizable profile length

- Belt conveyor exit system

- Safety barrier (Sensor)