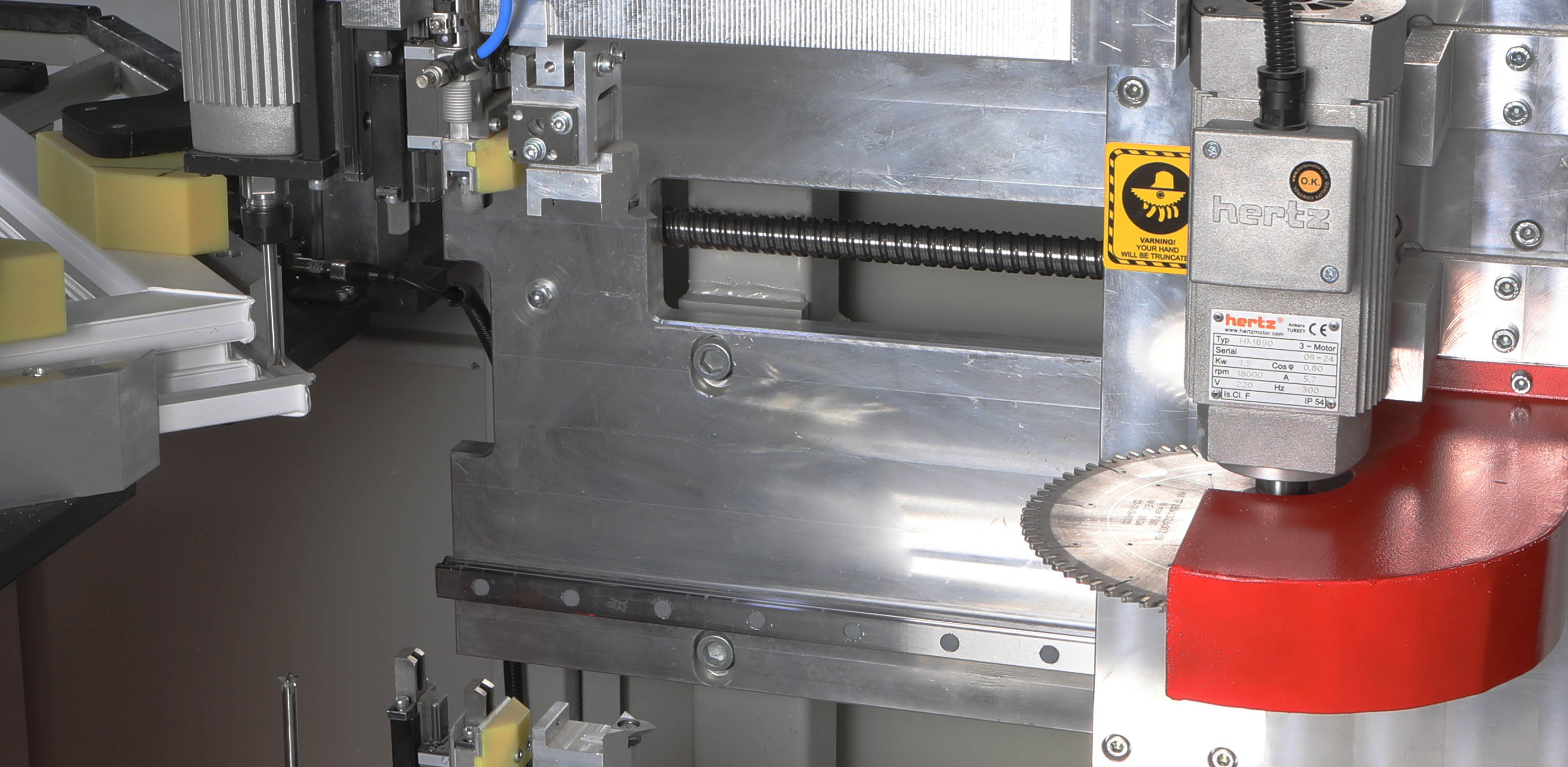

OST-600 can automatically clean the burrs resulting from melting during the corner cleaning process on PVC profile frames. It cleans inner and outer corners, as well as top, bottom, and all surfaces with high precision and high speed.

- CNC control system (2 Axis)

- Works with “G Code”

- It has the capacity to process 160-200 frames in 8 hours of working time.

- There are 10 cleaning sets in total.

- Cleaning the top and bottom surfaces for white profiles

- Cleaning the top and bottom surfaces of coated profiles

- Cleaning of inner and outer felt bearings

- Cleaning of angular and radius surfaces

- Unlimited memory capacity

- 10.1" LCD control screen provides ease of use for the operator

- Long life thanks to the automatic lubrication system. (Automatic lubrication is activated after 5 frame cleanings.)

- Linear guide system

- Simple use and programming thanks to its unique software

- There is a brush stand system to easily rotate the profiles.

- User friendly (Easy profile programming with Handle)

- Adjustable working speeds at desired speeds.